LFG Tech provides custom built fuel gas boosters for Caterpillar, Jenbacher and Waukesha landfill gas engines. Both Jenbacher and Waukesha typically require dehydration to meet the OEM humidity requirements and max gas tempuratures. All LFG engine fuel gas boosters need moisture control as part of the operations; however, Caterpillar operating requirements can be met with ambient temperature control and filtering. This substantially reduces operating cost.

The following pictures and simple diagrams provide the typical operational logic for a Caterpillar 3500 series engine and a Waukesha or Jenbacher engine:

Click here to request additional flare information or request a quote.

A new fuel gas booster for single CAT G3520, 550 SCFM:

Caterpillar Engine Fuel Gas Booster Simple Diagram

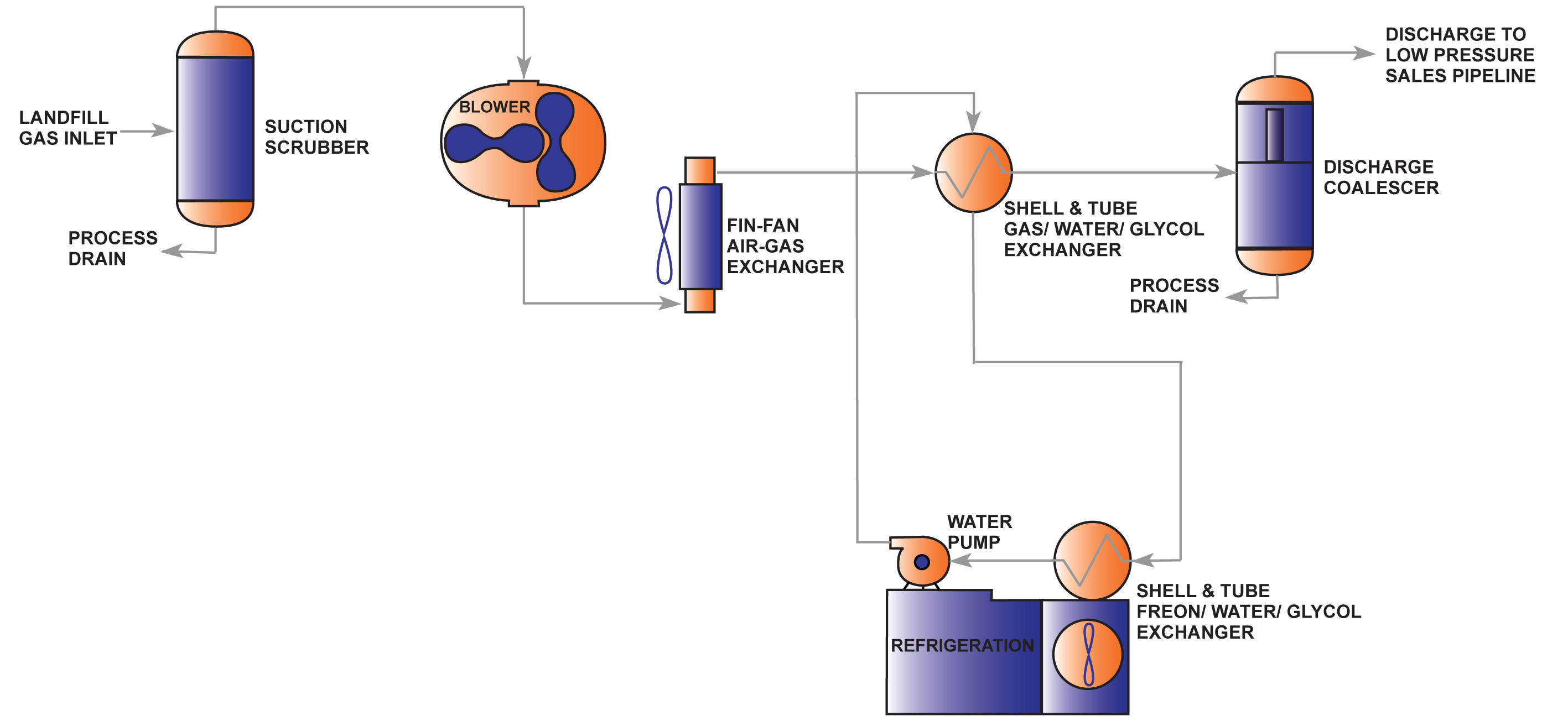

Jenbacher and/or MWM Engine Fuel Gas Booster Simple Diagram

Fuel Gas Booster Components to Consider:

Blower: Tuthill or Roots positive displacement blowers

Standard Murphy Control Panel: Class 1 Div II Panel

Custom PLC Control Panel: PLC Control with selection of PLC

Pressure Control Materials:

- Pneumatic pressure control with V-ball valve and controller or Variable Frequency Drive with back pressure regulator.

- All gas wetted parts 304 SS

- Fin/fan cooler tubes SS, box headers CS

- All valves CS with SS trim

- CS flanges